YIXUN MACHINERY Showcases Innovation As A High-Performance Warp Knitting Machine Manufacturer At ITMA

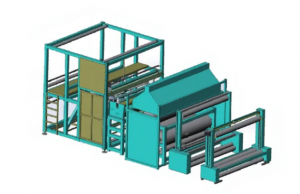

DANYANG, JIANGSU, CHINA, January 30, 2026 /EINPresswire.com/ -- Danyang Yixun Machinery Co., Ltd., a recognized High-Performance Warp Knitting Machine Manufacturer, recently highlighted its latest technological advancements at ITMA, the world’s most influential textile and garment technology exhibition. During this premier event, the company demonstrated its commitment to engineering excellence by showcasing specialized machinery designed for the production of technical textiles and composite reinforcements. As global industries increasingly pivot toward high-strength, lightweight materials, YIXUN MACHINERY’s participation at ITMA serves as a testament to its role in providing the critical infrastructure required for modern industrial manufacturing. The company’s flagship products, including multi-axial and bi-axial warp knitting systems, are engineered to process advanced fibers like carbon and glass fiber, catering to the rigorous demands of the aerospace, automotive, and renewable energy sectors.

Current Industrial Landscape: The Rise of Technical Textiles

The global textile machinery industry is undergoing a significant structural transformation. While traditional garment textiles remain a market staple, high-end engineering focus has shifted toward the "Technical Textiles" sector. This segment prioritizes functional properties over aesthetic appeal. High-performance warp knitting technology stands at the center of this revolution, allowing for stable, multi-layered structures that withstand extreme mechanical stress. As manufacturing moves toward a "Green Economy," the demand for composite materials to replace heavy steel or aluminum has reached an all-time high.

Technological trends are now dominated by precision and material efficiency. High-performance fibers like carbon fiber and glass fiber are expensive and delicate; therefore, machinery must offer impeccable tension control and fiber-spreading capabilities. Manufacturers today seek "intelligent" machines that minimize yarn breakage and raw material waste rather than just high speeds. This shift drives R&D focused on electronic let-off systems and computerized pattern control. Additionally, sustainability is a primary driver, with leaders seeking equipment that reduces energy consumption. The rise of "Smart Factories" requires machines compatible with real-time digital monitoring, ensuring resilient supply chains and predictive maintenance.

ITMA: The Global Nexus for Textile Machinery Innovation

ITMA is widely regarded as the most important event in the textile calendar, occurring only once every four years. It serves as a global barometer for the health and direction of the entire textile industry. For exhibitors, ITMA is the primary stage to launch new products and demonstrate technical superiority to a professional audience that includes factory owners, chemical fiber engineers, and material scientists. The exhibition covers the entire value chain, from fiber processing to finishing and logistics, making it an essential destination for any organization involved in the textile ecosystem.

The significance of ITMA lies in its ability to concentrate global expertise in one location. It is the place where a high-performance warp knitting machine manufacturer can engage directly with the end-users of their technology to understand the evolving challenges of the production floor. The event fosters a culture of international exchange, where standards for safety, efficiency, and environmental impact are often established. For companies originating from China’s high-tech manufacturing hubs, like Danyang, ITMA is a vital platform to prove that their domestic innovations meet the world’s most stringent quality benchmarks.

In recent years, ITMA has increasingly focused on "Advanced Materials" and "Digitalization." The exhibition floor has become a showcase for how traditional mechanical processes are being augmented by automation. This focus aligns perfectly with the needs of the composites industry, where the precision of the knitting process directly affects the structural integrity of the final product—be it a wind turbine blade or a high-speed train cabin. By participating in ITMA, manufacturers gain access to a global network of partners, ensuring that their innovations have a reach that spans across continents, from the industrial heartlands of Europe to the emerging manufacturing zones in Southeast Asia.

Corporate Excellence and High-Precision Manufacturing Standards

Danyang Yixun Machinery Co., Ltd. has dedicated itself to the R&D and production of top-tier textile machinery. As a National High-Tech Enterprise, the company has secured over ten invention patents, reflecting its deep-seated culture of innovation. YIXUN’S manufacturing philosophy is built upon the foundation of "Precision First." To achieve this, the company has invested heavily in advanced production equipment, including high-precision CNC machining centers, four-axis machining centers, and Coordinate Measuring Machines (CMM) for rigorous quality inspection.

This commitment to hardware ensures that every component of a YIXUN machine is built to endure the stresses of high-speed industrial operation. The company manages a highly efficient supply chain, with nearly all critical components sourced within a 20-kilometer radius of its Danyang plant. This localized ecosystem allows for superior quality control and a rapid response to customer requirements, ensuring that machine assembly and shipping occur on strict timelines. With an annual production capacity of over 220 sets, YIXUN has proven its ability to scale while maintaining the specialized attention to detail required for high-performance equipment.

Strategic Product Portfolio and Industrial Application Scenarios

The product line at YIXUN MACHINERY is categorized into eight major series, encompassing more than fifty specialized machine types designed to meet the technical requirements of high-growth industries.

Multi-Axial and Bi-Axial Warp Knitting Machines: These are the company’s flagship offerings. They are used to produce multi-layered reinforcement fabrics where fibers are laid at specific angles. These fabrics are essential for wind turbine blades, high-performance marine hulls, and automotive structural components.

Carbon Fiber Spreading Machines: Carbon fiber is difficult to handle due to its brittleness. YIXUN’s spreading technology allows for the uniform flattening of carbon fiber tows into ultra-thin tapes, used in aerospace applications and high-end sporting goods to achieve maximum strength with minimum weight.

Laid Scrim Machines: The facility produces lightweight glass fiber, polyester mesh products that are widely used in wall restoration, tape, floor stabilization, and industrial packaging.The grids provide the necessary tear resistance and dimensional stability to materials subject to environmental stress.

The effectiveness of these machines is demonstrated through adoption by major industrial clients. In the wind energy sector, YIXUN’s machines enable the manufacture of glass fiber fabrics required for offshore wind turbines. In the infrastructure sector, the company’s laid scrim machines have provided reinforcement for large-scale waterproofing projects. By focusing on quality and customer satisfaction, YIXUN MACHINERY provides complete technical solutions, including process consulting, installation, and long-term technical support.

Conclusion

The successful showcase at ITMA reinforces YIXUN MACHINERY’s standing as a premier high-performance warp knitting machine manufacturer. Through a combination of rigorous mechanical engineering, a localized supply chain, and a focus on the needs of the composites industry, the company has established a global reputation for excellence. As industries demand smarter and more precise ways to process advanced materials, YIXUN MACHINERY remains at the forefront, bridging the gap between innovative textile technology and industrial application. The company continues to empower the global manufacturing sector with the tools necessary to build a stronger and more sustainable future.

For further information regarding products and technical specifications, please visit the official company website: https://www.yixun-machine.com/

Current Industrial Landscape: The Rise of Technical Textiles

The global textile machinery industry is undergoing a significant structural transformation. While traditional garment textiles remain a market staple, high-end engineering focus has shifted toward the "Technical Textiles" sector. This segment prioritizes functional properties over aesthetic appeal. High-performance warp knitting technology stands at the center of this revolution, allowing for stable, multi-layered structures that withstand extreme mechanical stress. As manufacturing moves toward a "Green Economy," the demand for composite materials to replace heavy steel or aluminum has reached an all-time high.

Technological trends are now dominated by precision and material efficiency. High-performance fibers like carbon fiber and glass fiber are expensive and delicate; therefore, machinery must offer impeccable tension control and fiber-spreading capabilities. Manufacturers today seek "intelligent" machines that minimize yarn breakage and raw material waste rather than just high speeds. This shift drives R&D focused on electronic let-off systems and computerized pattern control. Additionally, sustainability is a primary driver, with leaders seeking equipment that reduces energy consumption. The rise of "Smart Factories" requires machines compatible with real-time digital monitoring, ensuring resilient supply chains and predictive maintenance.

ITMA: The Global Nexus for Textile Machinery Innovation

ITMA is widely regarded as the most important event in the textile calendar, occurring only once every four years. It serves as a global barometer for the health and direction of the entire textile industry. For exhibitors, ITMA is the primary stage to launch new products and demonstrate technical superiority to a professional audience that includes factory owners, chemical fiber engineers, and material scientists. The exhibition covers the entire value chain, from fiber processing to finishing and logistics, making it an essential destination for any organization involved in the textile ecosystem.

The significance of ITMA lies in its ability to concentrate global expertise in one location. It is the place where a high-performance warp knitting machine manufacturer can engage directly with the end-users of their technology to understand the evolving challenges of the production floor. The event fosters a culture of international exchange, where standards for safety, efficiency, and environmental impact are often established. For companies originating from China’s high-tech manufacturing hubs, like Danyang, ITMA is a vital platform to prove that their domestic innovations meet the world’s most stringent quality benchmarks.

In recent years, ITMA has increasingly focused on "Advanced Materials" and "Digitalization." The exhibition floor has become a showcase for how traditional mechanical processes are being augmented by automation. This focus aligns perfectly with the needs of the composites industry, where the precision of the knitting process directly affects the structural integrity of the final product—be it a wind turbine blade or a high-speed train cabin. By participating in ITMA, manufacturers gain access to a global network of partners, ensuring that their innovations have a reach that spans across continents, from the industrial heartlands of Europe to the emerging manufacturing zones in Southeast Asia.

Corporate Excellence and High-Precision Manufacturing Standards

Danyang Yixun Machinery Co., Ltd. has dedicated itself to the R&D and production of top-tier textile machinery. As a National High-Tech Enterprise, the company has secured over ten invention patents, reflecting its deep-seated culture of innovation. YIXUN’S manufacturing philosophy is built upon the foundation of "Precision First." To achieve this, the company has invested heavily in advanced production equipment, including high-precision CNC machining centers, four-axis machining centers, and Coordinate Measuring Machines (CMM) for rigorous quality inspection.

This commitment to hardware ensures that every component of a YIXUN machine is built to endure the stresses of high-speed industrial operation. The company manages a highly efficient supply chain, with nearly all critical components sourced within a 20-kilometer radius of its Danyang plant. This localized ecosystem allows for superior quality control and a rapid response to customer requirements, ensuring that machine assembly and shipping occur on strict timelines. With an annual production capacity of over 220 sets, YIXUN has proven its ability to scale while maintaining the specialized attention to detail required for high-performance equipment.

Strategic Product Portfolio and Industrial Application Scenarios

The product line at YIXUN MACHINERY is categorized into eight major series, encompassing more than fifty specialized machine types designed to meet the technical requirements of high-growth industries.

Multi-Axial and Bi-Axial Warp Knitting Machines: These are the company’s flagship offerings. They are used to produce multi-layered reinforcement fabrics where fibers are laid at specific angles. These fabrics are essential for wind turbine blades, high-performance marine hulls, and automotive structural components.

Carbon Fiber Spreading Machines: Carbon fiber is difficult to handle due to its brittleness. YIXUN’s spreading technology allows for the uniform flattening of carbon fiber tows into ultra-thin tapes, used in aerospace applications and high-end sporting goods to achieve maximum strength with minimum weight.

Laid Scrim Machines: The facility produces lightweight glass fiber, polyester mesh products that are widely used in wall restoration, tape, floor stabilization, and industrial packaging.The grids provide the necessary tear resistance and dimensional stability to materials subject to environmental stress.

The effectiveness of these machines is demonstrated through adoption by major industrial clients. In the wind energy sector, YIXUN’s machines enable the manufacture of glass fiber fabrics required for offshore wind turbines. In the infrastructure sector, the company’s laid scrim machines have provided reinforcement for large-scale waterproofing projects. By focusing on quality and customer satisfaction, YIXUN MACHINERY provides complete technical solutions, including process consulting, installation, and long-term technical support.

Conclusion

The successful showcase at ITMA reinforces YIXUN MACHINERY’s standing as a premier high-performance warp knitting machine manufacturer. Through a combination of rigorous mechanical engineering, a localized supply chain, and a focus on the needs of the composites industry, the company has established a global reputation for excellence. As industries demand smarter and more precise ways to process advanced materials, YIXUN MACHINERY remains at the forefront, bridging the gap between innovative textile technology and industrial application. The company continues to empower the global manufacturing sector with the tools necessary to build a stronger and more sustainable future.

For further information regarding products and technical specifications, please visit the official company website: https://www.yixun-machine.com/

DANYANG YIXUN MACHINERY CO.,LTD

DANYANG YIXUN MACHINERY CO.,LTD

+86 13401554989

yixun@yinxun-machinery.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.